In industrial environments, maintaining clean air is crucial for the health and safety of workers as well as the proper functioning of equipment. Coarse dust, made up of larger airborne particles such as dirt, pollen, and debris, can pose significant challenges in factories, warehouses, and other industrial settings. This is where Coarse Dust Filters come into play, serving as a vital component in air filtration systems that protect both people and machinery from the harmful effects of airborne contaminants.

The Importance of Air Quality in Industrial Settings

Industrial environments often involve processes that generate a significant amount of dust and particulate matter. From manufacturing and construction to mining and agriculture, these industries produce airborne particles that can lead to a variety of issues if not properly managed. Poor air quality can result in respiratory problems for workers, reduce overall productivity, and cause damage to sensitive equipment.

For employees, prolonged exposure to coarse dust can lead to health problems such as asthma, bronchitis, and other respiratory issues. In some cases, inhaling large amounts of dust over time can result in chronic conditions that can affect a worker’s long-term health and ability to work. This makes it essential for industrial facilities to implement effective air filtration systems that include Coarse Dust Filters as a key component.

On the equipment side, coarse dust can accumulate on machinery, leading to malfunctions, reduced efficiency, and increased wear and tear. Dust particles can clog ventilation systems, overheat equipment, and cause breakdowns, resulting in costly repairs and downtime. By capturing larger particles before they enter critical systems, coarse dust filters help maintain the performance and longevity of industrial equipment.

How Coarse Dust Filters Work

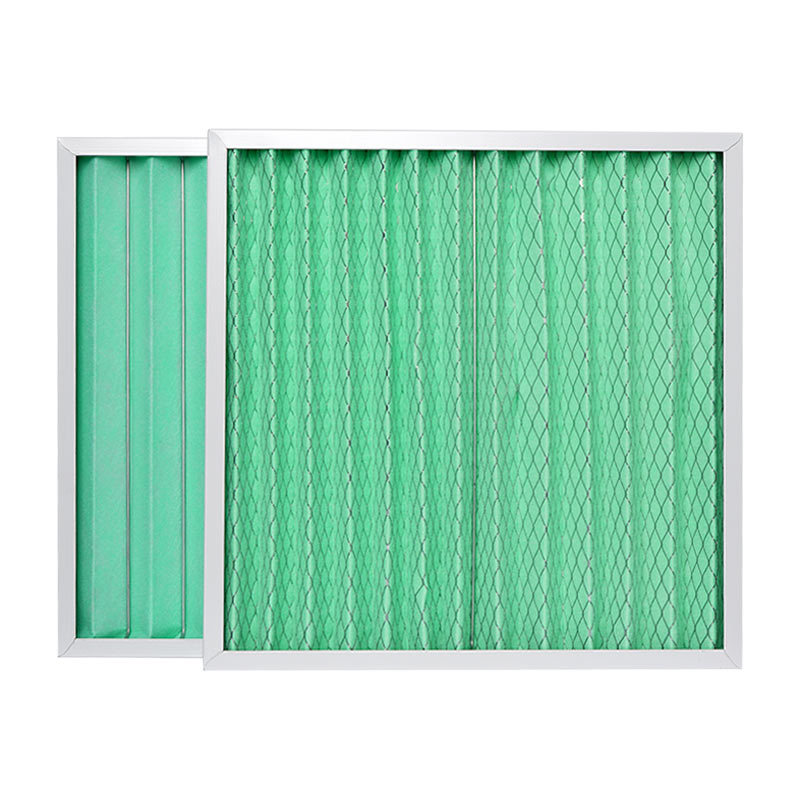

Coarse dust filters are designed to capture larger particles in the air before they reach more sensitive filtration stages or critical machinery. These filters typically use a mesh or fibrous material to trap particles ranging from 5 to 10 microns in size, such as pollen, dust mites, and large debris. Unlike fine dust filters, which are used to remove smaller particles such as bacteria and smoke, coarse dust filters focus on capturing the bulkier contaminants that are often present in industrial environments.

The filtration process begins when air passes through the coarse dust filter. The larger particles become trapped in the filter’s material, allowing cleaner air to continue through the system. In many industrial settings, coarse dust filters are the first line of defense in a multi-stage filtration system, protecting finer filters from becoming clogged by larger particles. This not only improves the overall efficiency of the air filtration system but also extends the lifespan of the more delicate filters.

Coarse dust filters are often used in conjunction with other filtration technologies, such as HEPA Filters or activated carbon filters, to create a comprehensive air filtration solution. By removing the larger particles first, coarse dust filters help ensure that the entire system operates more effectively, reducing the need for frequent maintenance and filter replacements.

Applications of Coarse Dust Filters in Different Industries

Coarse dust filters are used across a wide range of industries where air quality and equipment protection are critical. Some of the most common applications include:

Manufacturing: In manufacturing plants, especially those dealing with metalworking, woodworking, or textiles, large amounts of dust and debris are generated during production processes. Coarse dust filters help capture these particles, protecting machinery and ensuring a safer environment for workers.

Agriculture: Agricultural operations often produce large quantities of dust from soil, grain processing, and animal handling. Coarse dust filters are essential for maintaining clean air in barns, greenhouses, and processing facilities, where dust can negatively impact both workers and livestock.

Construction: Construction sites are notorious for producing airborne dust from activities such as demolition, excavation, and concrete mixing. Coarse dust filters in ventilation systems and equipment help reduce the spread of dust, protecting both workers and the surrounding environment.

Mining: Mining operations generate a significant amount of dust, particularly from drilling, blasting, and material handling. Coarse dust filters play a crucial role in maintaining air quality in these harsh environments, preventing dust from entering ventilation systems and machinery.

Warehousing and Logistics: Warehouses and distribution centers can accumulate dust from packaging materials, pallets, and general operations. Coarse dust filters help maintain a clean environment, which is essential for both product protection and employee health.

Food Processing: In the food industry, maintaining clean air is vital to ensure product quality and safety. Coarse dust filters are used in processing plants to capture dust from ingredients, packaging materials, and other sources, reducing the risk of contamination.

Enhancing Worker Safety and Productivity

One of the most significant benefits of using coarse dust filters in industrial environments is the improvement in worker safety. By reducing the amount of airborne dust, these filters help create a healthier work environment, minimizing the risk of respiratory issues and other health problems. This leads to a more productive workforce, as employees are less likely to experience illness or discomfort due to poor air quality.

In addition to protecting workers’ health, coarse dust filters also contribute to improved working conditions by reducing the need for constant cleaning and maintenance. In environments with high levels of dust, surfaces can quickly become covered in debris, leading to a time-consuming and labor-intensive cleaning process. By capturing dust at the source, coarse dust filters help keep workspaces cleaner and more organized, allowing employees to focus on their tasks rather than dealing with constant dust accumulation.

Protecting Equipment and Reducing Maintenance Costs

Another key advantage of coarse dust filters is their ability to protect industrial equipment from the damaging effects of dust and debris. When dust particles enter machinery, they can cause a range of issues, from reduced efficiency to complete breakdowns. Coarse dust filters prevent these particles from reaching sensitive components, helping to maintain optimal performance and reduce the likelihood of costly repairs.

By extending the lifespan of equipment and reducing the need for frequent maintenance, coarse dust filters offer a cost-effective solution for industrial facilities. The initial investment in high-quality filtration systems can result in significant savings over time, as equipment operates more efficiently and experiences fewer breakdowns. This is especially important in industries where downtime can have a substantial impact on productivity and profitability.

Advances in Coarse Dust Filter Technology

As industries continue to prioritize air quality and equipment protection, advances in coarse dust filter technology are making these systems even more effective. Modern coarse dust filters are designed to offer improved filtration efficiency, capturing a higher percentage of particles while maintaining airflow. This is achieved through the use of innovative materials and designs that maximize the surface area available for filtration without compromising performance.

One example of this is the development of pleated filters, which provide a larger surface area within a compact space. These filters can capture more dust particles before needing to be replaced, reducing maintenance frequency and costs. Additionally, new materials such as synthetic fibers are being used to create more durable and efficient filters that can withstand harsh industrial environments.

Customization and Sustainability in Coarse Dust Filtration

With the increasing demand for customized solutions, many manufacturers now offer coarse dust filters tailored to specific industrial needs. Whether it's a particular size, shape, or filtration capacity, customized filters ensure that businesses can address their unique challenges more effectively. Custom solutions also allow industries to integrate filtration systems seamlessly into existing equipment, improving overall efficiency and performance.

In addition to customization, sustainability is becoming a significant focus in coarse dust filtration. As businesses strive to reduce their environmental impact, manufacturers are responding by developing filters made from eco-friendly materials that are both recyclable and biodegradable. This shift toward sustainable filtration solutions helps companies meet environmental regulations and achieve their sustainability goals.

Conclusion

Coarse dust filters play a critical role in maintaining clean air and protecting equipment in industrial environments. By capturing larger particles before they can cause harm, these filters enhance worker safety, improve productivity, and extend the lifespan of machinery. With ongoing advancements in filtration technology, industries can expect even more efficient and cost-effective solutions to address their air quality challenges.

Implementing coarse dust filters is not just about complying with regulations—it’s about creating a safer, more efficient, and more sustainable workplace. As businesses continue to recognize the importance of air quality, coarse dust filters will remain a key component in industrial filtration systems for years to come.